vickers hardness test used for|vickers hardness test chart : wholesaler Vickers hardness testing has been widely used as one of the basic and reliable material test methods. Furthermore, triangular pyramidal indentation technique (the nanoindentation . Stealing the Diamond. Stealing the Diamond est le troisième volet de la populaire série de jeux Henry Stickmin. Aidez Henry Stickmin à pénétrer dans un musée et à voler des .

{plog:ftitle_list}

Old, single-lined slots had no reason to give false wins, wher.

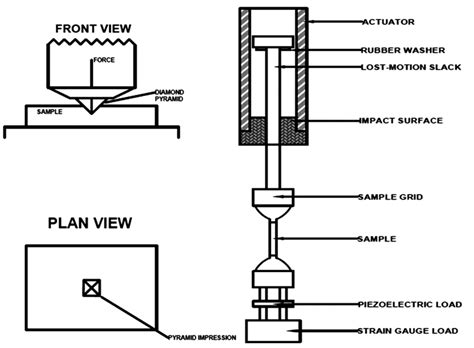

vickers hardness testing machine diagram

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .

vickers hardness test theory

Vickers hardness testing can be used for microhardness testing, allowing for the measurement of hardness in small or thin samples. This capability is essential for materials with limited sample sizes or complex geometries, such as thin .Vickers hardness testing has been widely used as one of the basic and reliable material test methods. Furthermore, triangular pyramidal indentation technique (the nanoindentation .

The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Vickers method is based on an optical measurement system.In most cases, the Vickers hardness test is used to determine hardness in materials in the micro hardness test load range. However, the Knoop hardness test is often used when hardness testing thin layers, such as .The Vickers hardness test is a method of measuring the hardness of a material by indenting it with a diamond indenter in the shape of a right pyramid with a square base and an angle of .

The Vickers hardness test. Vickers is a hardness test for all solid materials, including metallic materials. The Vickers Hardness (HV) is calculated by measuring the diagonal lengths of an indent in the sample material left by introducing a diamond pyramid indenter with a given load.

A method that can be used for figuring out a material’s hardness—a measurement of its resistance to deformation in the presence of force—is the Vickers hardness test. While it finds use in other materials like ceramics & some polymers, this test is widely employed in the metallurgical area.Vickers Hardness Testing Formulas, Calculator and Review . The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the .

vickers hardness test pdf

vickers hardness test explained

vickers hardness test lab report discussion

Vickers Hardness The Knoop hardness test is similar to the Vickers test but uses a rhombic-based diamond indenter instead of a pyr-amid. It is commonly used for measuring the hardness of thin coatings or materials with a small indentation requirement. Knoop belongs to the optical methods. Knoop Hardness

In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the indentation on the .

1.961 ≤ F < 49.03 N - Designation: HV 0.2 to

The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the test indentation is very small in a Vickers microhardness test, it is useful for a variety of applications such as: testing very thin materials like foils or measuring the surface . The Vickers hardness test involves the use a 4-sided square-based pyramid indenter, with a precisely defined constant force on the test specimen to evaluate the surface area of the indentation. The specimen is first lifted until it comes into contact with the indenter. The test force is then applied by the indenter to the test specimen, slowly .

Applications of Vickers Hardness Testing: Material Characterization: Vickers hardness testing is commonly used to determine the hardness of various materials, including metals, ceramics, and polymers.This information is crucial for understanding material properties, such as wear resistance, toughness, and strength.The hardness test developed by Friedrich Mohs was the first known test to assess resistance of a material to scratching. It is a very simple but inexact comparative test. Perhaps its simplicity has enabled it to become the most widely used hardness test. Since the Mohs Scale was developed in 1812, many different hardness tests have been invented.1.1 Vickers Hardness. The Vickers test employs a square-based pyramid with an angle of 136° between opposing faces. The Vickers hardness is defined as the applied load P divided by the surface area of the impression. In general, the diagonal d or the depth t of the impression is measured and, .

Hardness tests measure the resistance of a material against plastic deformation.To perform these tests (be it Brinell, Rockwell, or Vickers), an indenter is pressed on the surface of the specimen with a specific force F F F for a time interval of, say, 10-15 s.During this interval, the material undergoes plastic deformation, which you will measure after unloading the material .The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The article is all about the principle and application of Vickers hardness test. + 86 755 61301520; [email protected]; Search.3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually .

Vickers hardness testing is widely used because it provides accurate and repeatable results for various materials, regardless of their hardness. It's particularly useful for materials that are too hard or too brittle for other . The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness (1) The geometrical shape of the indentation .The Vickers hardness test method, otherwise called a microhardness test method, is used for small objects, thin sections, as well as the case depth work. Due to the small indentation in a Vickers test, it can test very thin materials like foils, small parts, small areas, or the surface of a part, and individual microstructures.

Microhardness: The Vickers test can be used to measure the hardness of small or thin samples, making it ideal for microhardness testing. Applications of Vickers Hardness Testing. Quality Control: Vickers hardness testing is extensively used in quality control and material certification processes, ensuring that materials meet specified hardness .

The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the test indentation is very small in a Vickers microhardness test, it is useful for a variety of applications such as: testing very thin materials like foils or measuring the surface .

The Vickers hardness test is done by pressing a particular indenter into the surface under testing. It only makes use of one test force, unlike with other types of hardness testing, such as the Rockwell hardness test. The resulting indentation is measured with the aid of eyepieces and high-powered magnifying instruments like microscopes.The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the .

The Vickers hardness test is a method of measuring the hardness of a material by indenting it with a diamond indenter in the shape of a right pyramid with a square base and an angle of 136 degrees between opposite faces. This test is used to provide a continuous scale of hardness for a given load, making it a popular choice for research work.ISO 6507-1 Metallic Materials—Vickers hardness Test— Part 1: Test Method 3.2.3 macroindention hardness test, n—a hardness test using ISO/IEC 17011 Conformity Assessment—General Require- test forces normally higher than 9.807 N (1 kgf). Macroinden- ments for Accreditation Bodies Accrediting Conformity tation tests include Vickers . Basic principle and practical procedure of the Vickers hardness test - Testing machine, test piece, diamond pyramid indenter - Basic principle, hardness de.

Introduction to Vickers Hardness Test The Vickers hardness test, developed in 1921 by Robert L. Smith and George E. Sandland of Vickers Ltd., provides an alternative to the Brinell hardness test with a simpler scale. While it can be used to test the hardness of metals and other hard materials, its main focus is on [.]The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in the surface

vickers hardness test diagram

vickers hardness test definition

web26 de out. de 2023 · コンピューター同士が「通信」をするために. 普段何気なく利用しているインターネット。この「インターネット」という仕組みは、一言で説明すると世界中のコンピューターとコンピューター(もしくはサーバー)をつなげた仕組みであると言えます。. 図1:インターネットとは?

vickers hardness test used for|vickers hardness test chart